| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : MEI-AL

Model Number : APL-850T

Place of Origin : CHINA

MOQ : 1set

Price : RMB8,500,000-10,500,000/set

Payment Terms : T/T

Supply Ability : 1set/6 months

Delivery Time : 180-200days

Packaging Details : Export Stander Packing

Output : 850T/month

Feature : Integrated quality control

Advantage : Cost-Effective

Anodizing Film Thickness : 8-12µm

Max Profile Length : 6500mm

Racking method : Manual racking system

APL-850T Horizontal Oxidation production line 8000*width*3600

一. Product Description:

1.Anodizing linerefers to a production line or system specifically designed for the anodizing process. Anodizing is an electrochemical process used to create a controlled oxide layer on the surface of metals, typically aluminum or its alloys, to enhance their corrosion resistance, improve surface hardness, provide decorative finishes, or facilitate bonding with other materials.

2.Anodizing production lines can accommodate different variations of the anodizing process.

3.Anodizing production lines may feature process monitoring systems that continuously monitor critical parameters such as current, voltage, temperature, and pH levels. If any parameter deviates from the set limits or predefined parameters, alarms or notifications are triggered to alert operators or maintenance personnel.

二. Design Condition

三. Process Tank

四.Treatment Process:

(6) Average anodizing layer : 0.36*1.3*26*0.77 =9.4um

1) Clour process: Mix Salts

2) Quantity:2 jig(rack)/tank x 1tanks = 2jig(rack)

3) Current density: 70A

4) Process time: 2-8min

6. Sealing

1) Sealing menthod: Sealing at Medium or Normal Temperature

2) Quantity:6jig(rack)/tank x 1 tank

3) Process time 10-15min

五. Design Parameter and Setting

1. Anodizing treatment area:

1) Each anodizing process tank need 33min ,where total jig(rack)/year:

( 2 rack x 3 tank x 60min/h) ÷33min x600 hour =6545jig(rack)

2) Design 51.4m²/jig(rack) . Where every tank is 102.8m²

3) Area treatment/year : 6545jig(rack)x 51.4m² /jig =336413m²

2. Anodizing treatment weight:

Monthly output : 336413m²÷350m²/T*0.9=865T≧850T

3. Power consumption:

1) Anodising Tank:100m²/tank* 130A/ m²÷0.9=14444A/tank

Power Rectifier : 15000A =3unit

2) Clouring tank: 100㎡/tank×70A/m²÷0.9 = 7777A/tank

Colour Rectifier : 8000A =1 unit

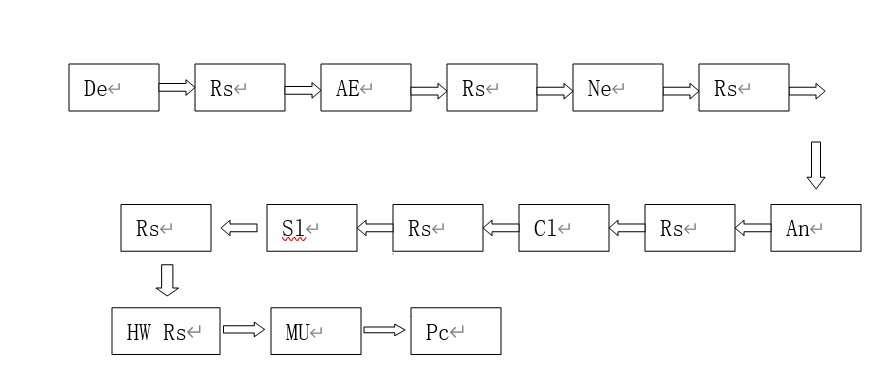

六. Process Chat

Discription for Un

1) De = Degreasing

2) Rs = Rinsing, HW Rs = Hot Water Rinsing

4) AE = Alkaline Etching

5) Ne = Neutralization

6) An = Anodizing

7) Cl = Coloring

8) Sl = Sealing

9) MU = Material Unloading

10) Pc = Packing

|

|

APL-850T Horizontal Oxidation Production Line 8000*width*3600 Images |