| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : MEI-AL

Model Number : 1000T/MONTH

Place of Origin : GUANGDONG MEI-AL ,CHINA

MOQ : 1set

Price : Negotiable

Payment Terms : L/C, T/T, Western Union, MoneyGram

Supply Ability : 1set/6 months

Delivery Time : 180-200days

Packaging Details : Export Stander Packing

Mode : Vertical anodizing

Thickness : 8-12µm

Aluminum Profiles Length : According to customers' requirement

Constructure : Provided

Voltage : 380V 50Hz or Customers Local Voltage

Colour Rectifier : 2 sets

Loading Method : Manual

Anodizing Temperature : 15-30℃

Control System : PLC

Heating Method : Electric Heating/ Gas Heating

Operation : Semi-automatic or full-Automatic

Ower Consumption : 10-30 kW

Warranty : 365 days

Process Type : mechanical,electrochemical ,chemical

Heating Way : steam,Electricity

Aluminum Anodizing Production Line Suface Treatment Equipment

1.Transportation industry: Anodized aluminum is widely used in the automotive industry for components like wheels, frames, cylinder heads, gear box housings, pistons, anti-lock brake components, transmission parts, radiators, and bumpers.

2.The aerospace industry also utilizes anodized aluminum for airframe skins, helicopter rotor blades, satellite components, landing gear, hydraulic control housings, avionic cases, and instrument panels.

3.Anodized aluminum is used in the manufacturing of refrigerators, microwaves, washers, dryers, coffee makers, televisions, and curling irons.

www.mei-alu.com

catalogue uploading:

PDF Gallery_20240719_102320.pdf01_0.pdf04.pdf07.pdf10_0.pdf12.pdf15_0.pdf18.pdf

二. Design Condition

| 1 | Alloy | Aluminium 6061 to 6063 or others |

| 2 | Anodizing film thinkness | 10-12um |

| 3 | Average coverage area | 350m²/T (ton) |

| 4 | Max aluminium profile length | 6500mm |

| 5 | Extrusion ratio | 2.5kg/m² |

| 6 | Working hour/m | 300d/m x 20h/d = 600h/m |

| 7 | Racking system | Two fixtures /rack |

| 8 | Racking operation | Manual |

| 9 | Equipment Usage Rate | 0.9 |

| 10 | Power supply | AC 3phase 380v 50hz |

| 11 | Control Power | AC220V 50Hz |

| 12 | Water supply | 2kg/cm²·G |

| 13 | Hot steam | 6kg/cm²·G |

| 14 | Compressor air | 6kg/cm²·G |

三.Process Tank

| 1 | Degreasing 【Free sulfuric acid 180±30 g/l】 | 1 Tank |

| 2 | Alkali etching 【Free alkali 40-60g/l,Al3+ 30-120g/】 | 2 Tanks |

| 3 | Neutralization【Free sulfuric acid180±20g/l】 | 1 Tank |

| 4 | Anodising 【Free sulfuric acid 140-180g/l,Al3+≤20g/l】 | 4 Tanks |

| 5 | Colouring 【stannous sulfate 3-8g/l,Free sulfuric acid 15-25g/l,PH 0.8-1.2】 | 2 Tanks |

| 6 | Medium Temperature Sealing【PH 5-6.5,Nickel ion0.8-1.3g/l,Fluorion0.3-0.7 g/l】 | 3 Tank |

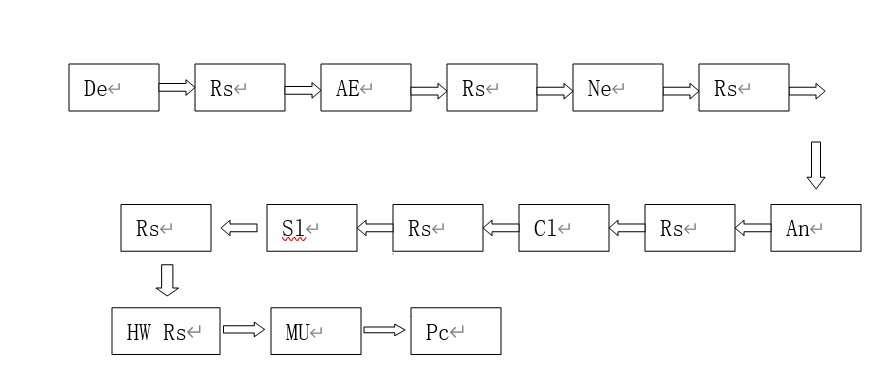

四. Process Chat

| Discription for Un | ||

| 1 | De | Degreasing |

| 2 | Rs | Rinsing |

| 3 | HW Rs | Hot Water Rinsing |

| 4 | AE | Alkaline Etching |

| 5 | Ne | Neutralization |

| 6 | An | Anodizing |

| 7 | Cl | Coloring |

| 8 | Sl | Sealing |

| 9 | MU | Material Unloading |

| 10 | Pc | Packing |

|

|

PLC Control System Aluminum Profiles Surface Treatment Process Images |